I bought an old Federal dial indicator from a retired machinist that had a big flat donut-shaped magnet glued on its back. I almost passed it up because it was kind of ugly, but it has turned out to be one of the most useful tools in my workshop. It is particularly useful for adjusting the Z-axis height on my Harbor Freight mini-mill.… Read the rest

I bought an old Federal dial indicator from a retired machinist that had a big flat donut-shaped magnet glued on its back. I almost passed it up because it was kind of ugly, but it has turned out to be one of the most useful tools in my workshop. It is particularly useful for adjusting the Z-axis height on my Harbor Freight mini-mill.… Read the rest

Mini-Mill Mods

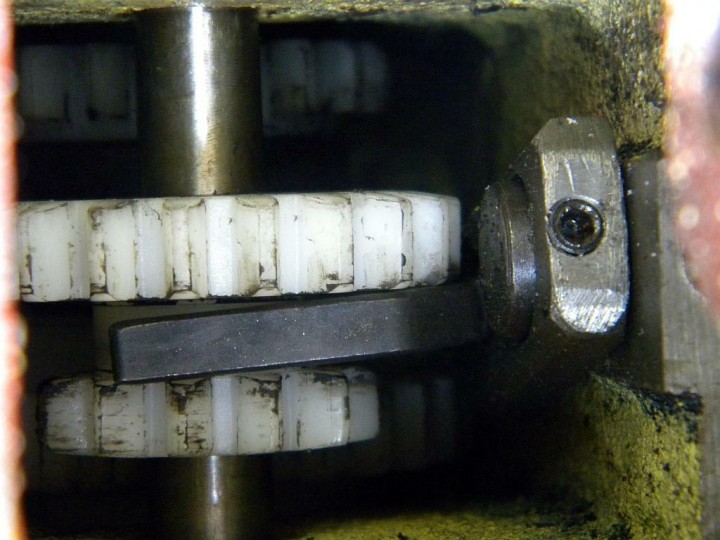

How-to: Remove the intermediate gear from a mini-mill

This photo essay will show you how to remove the intermediate gear and shift lever from the head of a Sieg Industries X2 mini-mill [HF 44991, Grizzly G8689, Micro-Mark & others]. It also explains why you might want to do so after installing a belt-drive. You may also find it useful if you need to replace a broken intermediate gear.… Read the rest

How-to: Install a belt-drive on a mini-mill

I wanted to move the belt drive from my old mill to my new CNC mini-mill. Well, the spindle nut didn’t want to come off, which didn’t make sense because I didn’t have any problems putting it on six months earlier. I went looking for pictures and advice on the Internet and had trouble finding any. … Read the rest

Inexpensive DIY tachometer for a mill or lathe

Here’s an idea I haven’t seen before. Adam made a very inexpensive tachometer for his variable speed X2 mini-mill using a cyclometer (bicycle speedometer). Almost any wired cyclometer will work and you should be able find one with a nice big display for about $15 or less. (You probably don’t want to get a wireless cyclometer because they’re more expensive, you’ll have an extra battery to replace occasionally, and you might get erroneous readings caused by the receiver picking up electrical noise from your motor).… Read the rest