This article describes how I made two round disks on my lathe out of sheet metal that was too thin to be held in a lathe chuck. I also could not use a mandrel because one of the disks was not going to have a hole drilled through its center. The two disks were made from .073-inch thick aluminum sheet metal and are about 5-inches in diameter. … Read the rest

Tips & Tricks

Clamping Thin Work on the Mill – Two Methods

I recently needed to mill down the thickness of a 7-inch long piece of steel from .25-inches to .20-inches. As the metal became thinner I started getting chatter and a bad finish on the ends because they were not being supported enough by my 3.5-inch wide precision screwless vise and 6-inch parallels.… Read the rest

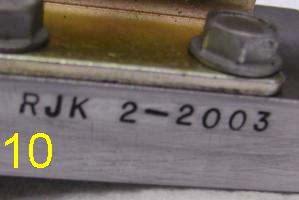

Hand Stamping Tips

I couldn’t resist buying a steel letter/number stamping set from Harbor Freight. They are not very expensive to begin with and I think I bought a set on sale for three or four dollars. It turns out I did not really have a clue how to use them until I read this article. … Read the rest

A Tool for Shortening Screws

I like to use socket head cap screws. Rather than keeping an expensive assortment of different lengths on hand, I usually stock a smaller selection and just cut a longer screw down to the length I need. Frank Ford has a great idea for making that process easier. His step plate makes consistent length screws and it fixes any thread damage done by the hacksaw.